Threading

- Home

- Capabilities

- Threading

Our Capabilities

Downloads

SEND US YOUR PRINTS AND WE WILL QUOTE THEM FOR YOU

Elevate Your Metalworking with Our Expert Threading Services

What is Threading?

Threading is a very common metalworking technique. A diverse assortment of connectors and fittings are now available on the global market. As a result, identifying the proper threads for your applications becomes increasingly difficult.

A helical ridge that runs continuously is called a thread. A helical ridge often has a section that is uniform across all of the distinct surfaces of a cylinder or cone. It is possible for it to form on either the interior surface of the nut or the external surface of the screw or bolt.

The basic role of a thread is to perform the function of a coupling between two different mechanisms. When you think about the cap on your water bottle, an interesting image of threads will come to mind. A watertight seal is created when the cap and the bottle top are coupled together.

Types of Machining Threads

Internal Thread Machining

Internal thread machining requires a twist drill, a 90° countersink, an internal hand or machine tap, an adjustable tap wrench (for hand) or a hand drill (for machine), and safety goggles.

Before threading, you must determine the tap to use and the diameter of the hole. Internal taps are labeled according on their nominal size. The core hole diameter = Tap diameter – Thread pitch formula may be used to calculate the diameter or twist drill for tapping.

Internal threads are also accessible on CNC turning components; many of the principles for cutting a thread on a lathe machine are the same as those for machining threads, but the thread requirements are more restrictive.

External Thread Machining

If you have a turning lathe, reduce the diameter to around 0.1 times the pitch of the thread. Threading tools for external threads include a file, round rod, clamping vise, round die, die stock, flat-tip screwdriver, and cutting spray.

1. File the round rod’s edges and chamfer it at 45°, slightly larger than the thread depth.

2. Firmly clamp the round die onto a die stock, then move the round die clockwise onto the round rod with enough pressure to sever the thread. Make certain that the thread is cut straight. Cutting spray can be used to improve surface quality and increase tool life in this situation.

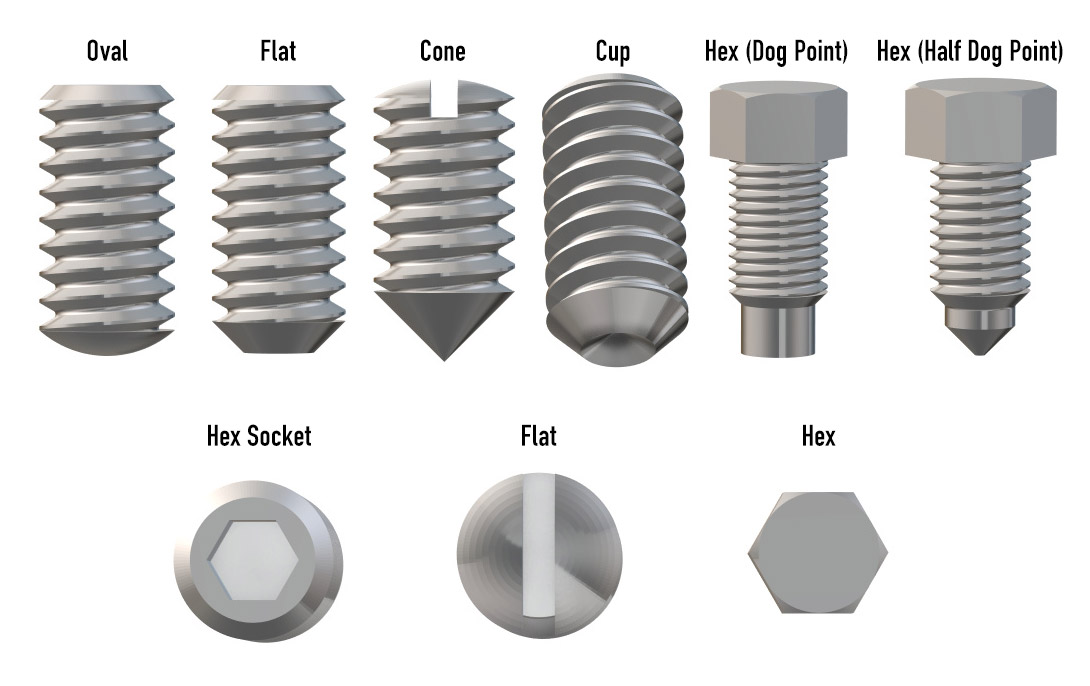

What are Types of Fasteners Threads

Clark Engineering has the capability to produce threads over one inch in diameter on our Landis thread cutting machines. We also have high speed magazine thread rolling machines that can produce threads up to four inches long on a ½ inch diameter rod.

This capability allows us to provide the lowest possible cost solution to our customers and ensures that the threading operations are kept in house and under our strict quality standards. Producing a high-quality roll thread is a science all in itself.

Our 60 years of experience in threading and our detailed inspection process allows us to produce a very high quality thread in complex applications.

Talk to an Expert

Fill out the form below and our account management staff will reach out to you shortly.