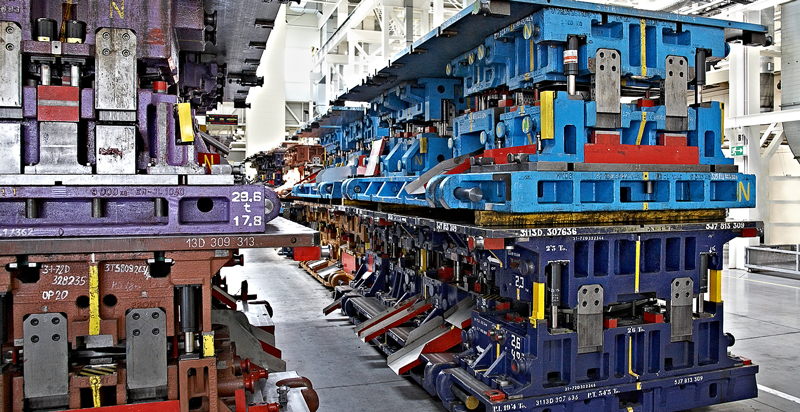

The metal stamping industry has become much more efficient over the years. We have new machines and technologies that make the final products affordable, more finished, and better in every way possible. Because of so many different options, the manufacturers can now choose from various options.

They are now using sophisticated machines to optimize the processes using servomotors, cams, and various tools for control. One of the most commonly used ones used in these manufacturing processes is the multi-slide and four-slide stamping machines.

These machines are used in processes for bulk volume production, making the four-slide and multi-slide stamping machines a popular choice. In this article, we will discuss these machines and their applications on industrial levels. Have a look:

Multi Slide Stamping: Digging into it

The Multi-Slide Metal Stamping process is relatively more complicated than other stamping metal processes. It is mainly because of the machine’s design difference. In the four-slide or multi-slide, the metal or wire you wish to stamp is approached from different angles and sides by the dies.

The stamp can be approached one by one or all simultaneously, depending on how the manufacturers want the machine to operate and its capabilities.

The manufacturers can also get the final wire design either in bent form or in the shape of a coil. It all depends on the die you use within the process.

The multi or four-slide technology is one of the most suitable options for manufacturers that want minimal-sized products from the machine and multiple bends on the metal or the wire after the stamping.

The more efficient multi-slide and four-slide stamping machines are, the more shapes they can add to the mix without complicating the stamping process.

With this method, you can create some of the finest machine accessories and metal products, such as:

Because of their wide range of applications, the machine is now used in all kinds of industries worldwide.

The multi-slide and four-slide stamping processes are so unique that they can produce some of the finest designs.

Many parts in this manufacturing process use conventional punch presses that reduce costs and make it a minor complex without this option.

However, with the equipment in the four-slide stamping process, four different tools work together for the stamping process and optimize the overall production.

The unique design makes it easier for the manufacturers to get plenty of benefits from the process. However, these benefits may vary from industry to industry. To help you understand them better, we will discuss them ahead of time.

Stamp Machining Types and their Benefits

The four stamping and multi-sliding machines are the most popular, with manufacturing processes requiring unique and intricate designs. These machines can stamp and bend the metals as needed at a much more affordable price.

These machines are also great because they are raw material efficient. It means they require less raw material to design the required products, which is ideal for cost-effective manufacturing. It also minimizes the amount of metal wasted within the manufacturing process and optimizes the entire process’s cost-effectiveness.

Less wastage and metal efficiency are best for more expensive materials, such as Rhodium and other alloys. The manufacturers can use the cost saved in other processes and ensure their manufacturing plants operate better for longer.

The dies within the multi-slide and four-slide also perform various tasks, contributing to their flexibility in product design.

With one machine catering to more designs, the cost of manufacture reduces significantly, granting users a high volume for production. Some of these machines can produce around 15,000 pieces every hour.

It makes the four-slide and multi-slide stamping best for mass production. The manufacturers can learn about the machine’s efficiency before purchasing it.

Moreover, these machines also tend to execute different operations in forming, reducing the time needed for production. With less time, the units can produce more pieces and optimize the overall industrial process.

Moreover, these machines don’t require additional tools and add-ons that can average thousands of dollars.

Micro-tooling Capabilities of the Four-Slide and Multi-Slide

The four-slide and multi-slide machines provide a variety of functions and manufacturing processes, making them ideal for various kinds of processes. These include refinement or micro-tooling, which can increase the manufacturers’ production while reducing the costs to a minimum amount.

For instance, one of the latest studies regarding multi-slide stamping focused on the client’s specific requirements. The client wanted to use pre-cut wires and solder them manually.

However, the manual process would take more time and cost more in general. The slowed process and the higher costs can increase labor costs and cut down the overall profit margin within the project.

In cases like these, the manufacturers can use the multi-slide press and the other machines in commercial manufacturing to change the wires. However, the manufacturers will still require soldering in this case. However, by changing the wires, the cost and the manufacturing time were reduced drastically.

Once this was completed, the clients joint the metal surfaces onto a single component that created a bridge-like surface. The bridge was connected by utilizing a solder-bearing material.

Micro tooling, which is now possible thanks to the delicate operations of the latest four-slide stamping process, lets the clients maximize their production by speeding up the process and still providing quality finished products.

Once the clients learn how to maximize their production process and budget, the time and cost required for stamped metal projects also reduce drastically.

Bottom Line

The multi-slide four-slide stamping process is a new and new process that provides better efficiency, newer designs, and several benefits in the manufacturing process.

If you’re looking for a reliable and efficient method to manufacture complex metal parts, consider Multi-Slide and Four-Slide Stamping. Contact us today to discuss how we can help you achieve your manufacturing goals with these cutting-edge processes.